PA66+30%GF fireproof V0 grade material

Fireproof V0 Grade Material Fire Fighting Equipment Parts Venting Valve

The venting valve is made of PA66+30%GF material. Its main function is to regulate and discharge the gas in the system, so that the fire-fighting equipment can maintain stable pressure and flow during normal operation. PA66, polyamide 66, is a thermoplastic with high strength and stiffness. After adding 30% glass fiber (GF), its mechanical properties and thermal stability are further improved, allowing the venting valve to maintain stable performance in complex and changeable working environments. The fire protection level of the venting valve is V0, which means that when burning vertically under specified test conditions, the flame will automatically extinguish within 10 seconds, and the burning drippings will not cause the filter paper to burn. These characteristics enable the venting valve to effectively prevent the spread of fire and gain valuable time for fire extinguishing work.

Product Description

We also custom Fireproof V0 Grade Material Fire Fighting Equipment Parts Venting Valve for our busienss to business customers.

-

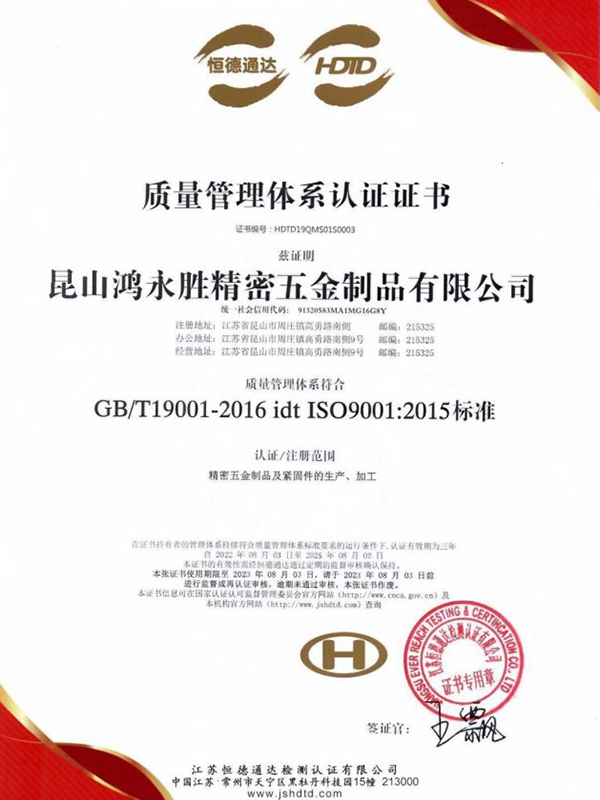

Kunshan Hong Yong Sheng Precision Hardware Products Co., Ltd. officially resumed operations with a traditional opening ceremony at its facility. The celebration began at the factory entrance, where fi...

READ MORE -

How to Use Rivets Without a Gun in Field Conditions When a pop rivet gun is not available, rivets can still be installed using alternative mechanical methods. This approach is suitable for light-duty ...

READ MORE -

Understanding Different Types of Nuts and Bolts Nuts and bolts form the backbone of mechanical fastening systems across countless applications, from household furniture to automotive assemblies and in...

READ MORE -

Introduction to #10 Screws #10 screws are one of the most commonly used fasteners across industries such as construction, woodworking, automotive, electronics, and manufacturing. Knowing the diameter,...

READ MORE -

Understanding Concrete Anchor Bolts and Anchors Concrete anchor bolts are widely used to fasten structural elements, machinery, and fixtures to concrete surfaces. They provide strong mechanical connec...

READ MORE

русский

русский Español

Español