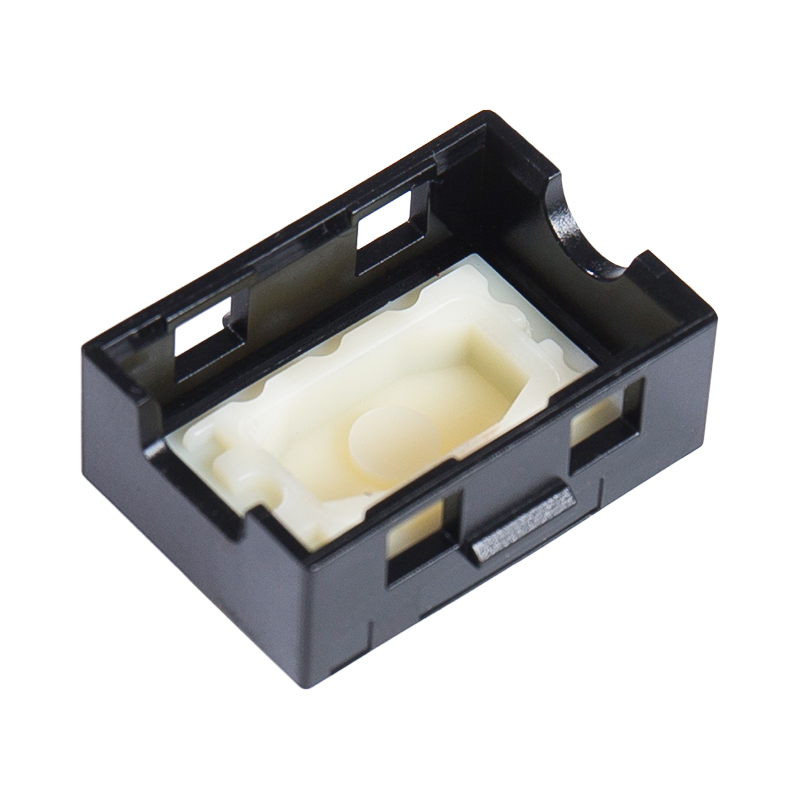

PC/TPR

PC/TPR Material Overmolding Equipment Buttons

The button is a common injection molded part, made of two materials: PC (polycarbonate) and TPR (thermoplastic elastomer). PC, as the outer material, has both wear resistance, weather resistance and chemical corrosion resistance. At the same time, the PC material also has good transparency, making the buttons more beautiful and high-end in appearance. TPR, as the inner material, gives the keys good touch and elasticity, making users feel comfortable when pressing. It also improves the anti-slip performance of the keys and enhances the user's operating experience. The key materials have strong adhesion, are not easy to fall off, and are not easy to age and deform. They are widely used in electronic products, home appliances, automobiles and other fields.

Product Description

We also custom PC/TPR Material Overmolding Equipment Buttons for our busienss to business customers.

-

Introduction to Copper, Steel, and Brass Nuts Nuts are essential fasteners used in various mechanical, electrical, and construction applications. Among the most commonly used materials are copper, ste...

READ MORE -

Introduction to Carbon Steel Screws Carbon steel screws are widely used in construction, industrial machinery, and heavy-duty assemblies due to their exceptional strength, versatility, and cost-effect...

READ MORE -

Carbon Steel Bolt Supplier Guide: What Buyers Should Look For Selecting the right supplier for carbon steel bolts affects product performance, safety, and long-term cost. This guide breaks down the p...

READ MORE -

Introduction: The Foundation of Mechanical Systems In the intricate world of modern manufacturing and engineering, machined parts form the fundamental building blocks of virtually every mechanical sys...

READ MORE -

Why Structural Integrity Matters In construction, machinery, and other industrial applications, structural integrity is crucial for safety, performance, and longevity. One of the key elements in ensur...

READ MORE

русский

русский Español

Español